| MODEL | MTP/MONO/ 75 | MTP/MONO/GF 80 | MTP/MONO/GF 90 |

|---|---|---|---|

| Production Output (Kg./Hr.)** | 125** | 225 | 275*** |

| Max Line Speed (MPM) | 150 | 150 | 150 |

| No. of Godet Rollers | 5/7 | 5/7 | 5/7 |

| Power (Kw)* | 147.75 | 194.72 | 243.25*** |

| Weight (Approx.) Kgs. | 9000 | 16500 | 17000 |

| Dimension (LxWxH in Mtr) | 19.2 x 3.5 x 3.2 | 20 x 4.2 x 3.9 | 23 x 4.2 x 3.9 |

NOTE: ***POWER LOAD & PRODUCTION CONSIDER WITH TWIN DIE HEAD **PRODUCTION CALCULATED WITH ROW MATERIAL HAVING MFI 3 AND ABOVE WITH MELT PUMP **PRODUCTION OF PE MONO CALCULATED AT 550 DENIER **POWER LOAD CALCULATED WITH MELT PUMP

User friendly touch screen display with separate desk.

All parameters and reading will be shown on display.

Precise denier output will be shown in display.

Recipe based operating system for easy machine operating.

Pneumatically operated transparent safety fence guard for godet rollers.

Emergency full length foot switches parallel to the godet length for both godets.

Energy calculation for production and power cost on display screen.

3 zone pressure transmitters for precise control & denier accuracy.

Vector speed control system for more stretching accuracy.

Inter-locking features to avoid the damages of machine components.

Shift wise, daily, weekly and monthly production reports.

AC drive fault alarm indication on display.

Wi-Fi or LAN connectivity.

Remote monitoring/remote maintenance.

User access with password protection.

Extra Features for Smooth and Easy Start.

Hopper loader.

Valve type screen changer with back flushing arrangement.

Melt pump with pressure transmitter device.

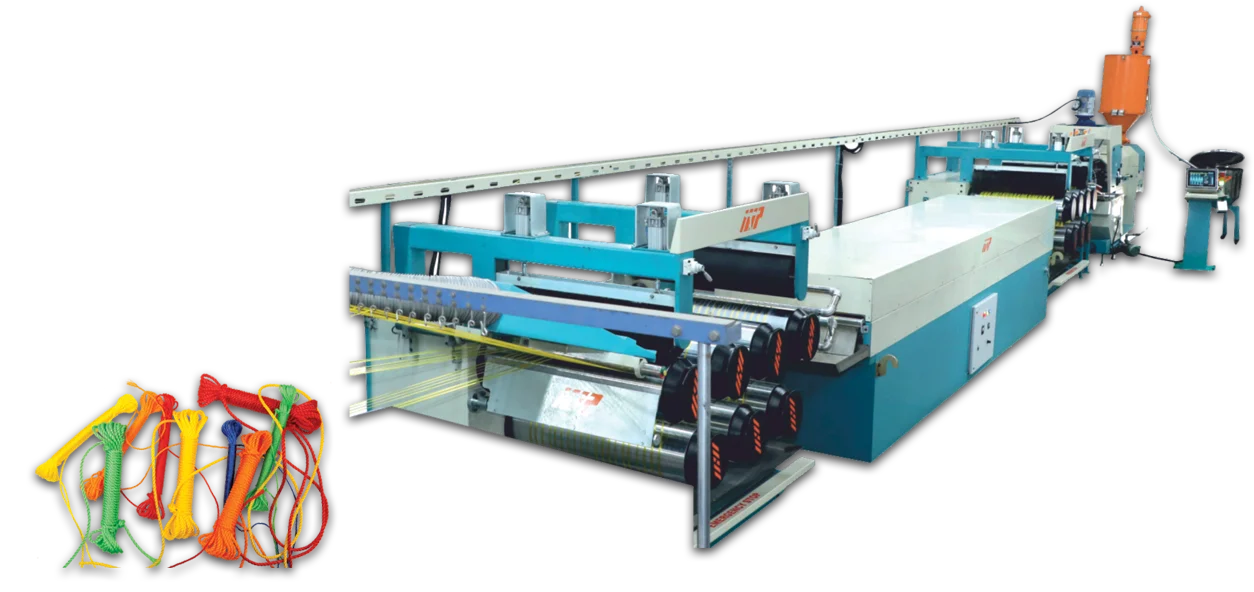

Monofilament die & head.

Quenching tank with up-down arrangement.

Godet-I-with 5 Nos, pulleys and pneumatically operated press roller.

Hot water tank with panel.

Godet-II- with 7 Nos. Pulleys and pneumatically Operated press rollers.

Electric control panel with multi-function energy meter and programmable logic control system.

Operating desk with color resistive touch screen HMI.